From P2P Foundation/ Blogger Ref http://www.p2pfoundation.net/Transfinancial_Economics

Contents[hide] |

Intro

And this leads us to part 3: Economic Organization & Calculation.[1]Transcript of the lecture by Peter Joseph:

Now, if you are wondering why I spent so much time on the prior points of post-scarcity and those two core problems inherent to market capitalism: Social Imbalance and Environmental Imbalance – its because you cannot understand the logic of the economic factors involved in this model, without those prior awarenesses. A Natural Law Resource Based Economy is not just a progressive outgrowth of our increased capacity to be productive as a species, as though we would just gradually evolve out of the market system, step by step, into this approach...

No. The dire need for this system’s removal needs to be realized once again. It has to become a part, in fact, of the incentive structure of the new model - the historical understanding that if we do not adjust in this way, we will revert right back into this highly unstable periods we are in right now.

An economic model is a theoretical construct representing component processes, by a set of variables or functions, describing the logical relationships between them. Basic definition.

If anyone has studied traditional or market based economic modeling, a great deal of time is often spent on things such as price trends, behavioral patterns, utlitarianistic functions, inflation, currency fluctuations and so forth. Rarely, if ever, is anything said about public or ecological health. Why? Because the market is again life-blind and decoupled from the science of life support and sustainability. It is simply a proxy system.

The best way to think about a this [new] economy is not in the traditional terms... but rather as an advanced production, distribution, and management system which is democratically engaged by the public through a kind “participatory economics” - that facilitates input processes – such as design proposals and demand assessment - while filtering all actions through what we will call “sustainability” & “efficiency” protocols.

These are the basic rules of industrial action set by natural law... not human opinion. As noted prior, neither of these interests are structurally inherent in the capitalist model and it is clear that humanity needs a model that has this type of stuff built right into it for consideration.

Structural System Goals

All economic systems have structural goals, which may not be readily apparent.Market Capitalism's structural goal, as described, is growth and maintaining rates of consumption high enough to keep people employed at any given time and employment requires, also, a culture of real or perceived inefficiency... and that essentially means the preservation of scarcity in one form or another. That is its structural goal and good luck getting a market economist to admit to that. This model’s goal is to optimize technical efficiency and create the highest level of abundance we possibly can, within the bounds of earthly sustainability, seeking to meet human needs directly.

System Overview

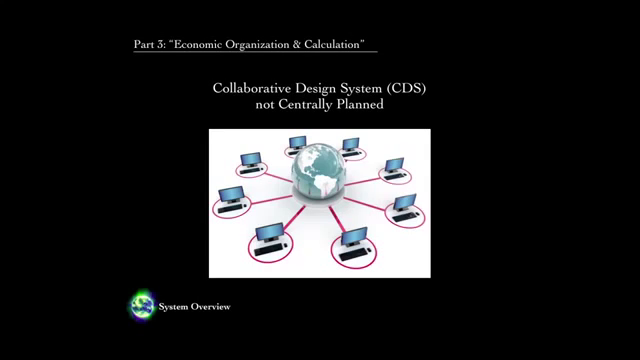

One of the great myths of this model is that it is “centrally planned”. What this means, based on historical precedent, is that it is assumed that an elite group of people basically will make the economic decisions for society. No. This model is a Collaborative Design System (CDS), not centrally planned. It is based entirely upon public interaction, facilitated by programmed, open source systems, that enable a constant, dynamic feedback flow that can literally allow the input of the public on any given industrial matter, whether personal or social.Now, a common question when you bring that up they say “Well, who programs this system?”. The answer is everyone and no one. The tangible rules of the laws of nature, as they apply to environmental sustainability and engineering efficiency, is a completely objective frame of reference. The nuances may change to some degree over time- but the general principles remain.

Over time, the logic of such an approach will become more rigid as well because we learn more as we perfect our understandings- and hence less room for subjectivity in certain areas that might have had it prior. Again, I’ll be describing this more so in a moment.

Also, the programs themselves would be available in an open source platform for public input and review. Absolutely transparent. And if someone noticed a problem or unapplied optimization strategy, which would probably be the case, it is evaluated and tested by the community - kind of like a wikipedia for calculation except much less subjective than wikipidea, without the moody administrators.

Another traditional confusion surrounds a concept which has become, to many, the defining difference between capitalism and everything else – and it has to do with whether the “means of production” is privately owned or not. And this is replete throughout tons of traditional literary treatments on capitalism when they describe how it’s the ultimate manifestation of human behavior in a society.

If you don't know whist this means, the means of production refers to the non-human assets that create goods, such as machinery, tools and factories, offices and the like. In capitalism, the means of production is owned by the capitalist, by historical definition and hence the origin of the term.

I bring this up because there has been an ongoing argument for a century that any system which does not have its means of production owned, as a form of private property, is just not going to be as economically efficient as one that has or maybe not even efficient at all.

This, as the argument goes, is because of the need for price, the price mechanism.

The price mechanism

Price, which has a fluid ability to exchange value amongst virtually any type of good due to its indivisibility of value, creates indeed a feedback mechanism that connects the entire market system in a certain narrow way. Price is a way to allocate scare resources amongst competing interests, for sure.Price, property, and money translate, in short, subjective demand preferences into semi-objective exchange values. I say semi, because it is again a culturally relative measure only- absent most every factor that gives true technical consideration to a given material or good. In other words, it has nothing to with what the material goods are it’s just a mechanism.

Perhaps the only real technical data in fact I would say that price embraces, very crudely, relates to ”resource scarcity” and “labor energy,” resource scarcity and labor energy, you can basically find that in price.

So, in this context, the question becomes, moving on, is it possible to create a system that can equally, if not more efficiently, facilitate feedback with respect to consumer preference, demand, labor value, and resource or component scarcity... without the price system, subjective property values, or exchange? And of course there is. The trick is to completely eliminate exchange and create a direct control and feedback link between the consumer and the means of production itself. The consumer becomes part of the means of production and the industrial complex, if you will, becomes nothing more than a tool that is accessed by the public to generate goods.

In fact, as alluded to prior, the same system can be used for just about any societal calculation, virtually eliminating the state government in fact and politics as we know it. It is a participatory decision making process.

And, as an aside, as far as the fact that there will indeed always be scarcity of something in the world, which is the very basis of existence of price, market, and money - human beings can, again, either understand the dire need to exist in a steady- state relationship with nature and the global human species for cultural & environmental sustainability ....or not.

We can either continue down the same path we are now and become more aware and responsible to the world in and each other.

Seeking post scarcity and using natural law rules of sustainability and efficiency to decide how to best allocate our raw materials or not. But I think the former is the most intelligent path. I state that because, again, this resource argument always comes down to the abstraction of resources, it never, excuse me, the abstraction of scarcity, it never qualifies what scarcity is in certain contexts. It doesn’t separate scarcity and that’s its fatal flaw between human needs and human wants.

Also, I want to point out another fallacy which of this “private ownership of the means of production,” a fallacy of this means of this broad concept is its culture lag. Today, we are seeing a merger of Capital Goods, Consumer Goods, and Labor Power. Machines are taking over human labor power, becoming capital goods, while also reducing in size to become consumer goods.

I’m sure most everyone in this room has a home paper printer. When you send a file to print from your computer, you are in control of a mini version of a means of production.

What about 3D printers? In some cities today, there are now 3d printing labs, which people can send their design to print in physical form.

The model I am going to describe is a similar idea. The next step is the creation of a strategically automated industrial complex, localized as much as possible, which is designed to produce, through automated means, the average of everything any given region has found demand for. Think about it. On-demand production on a mass scale. Consider for a moment how much storage space, transport energy, and overrun waste is immediately eliminated by this approach. I think the days of large, wasteful, mass producing economies of scale are coming to an end... well... if we want them too.

This type of thinking –true economic calculation, by the most technical sense of the term, I can’t reiterate that enough. We are calculating to be as technically efficient and conservative as possible, which again, almost paradoxically, is what will facilitate a global access abundance to meet all human needs and beyond.

Structure and Processes

Structure and Processes, moving on. So, I’m going to walk through the following three processes.- Collaborative Design Interface and Industrial Schematic

- Resource Management, Feedback, & Value

- General Principles of Sustainability and the Macro-Calculation.

This is how demand is accessed. It’s feedback, and it’s immediate.

Instead, of course, of advertising and the unidirectional consumer good proposal system, which it is – that we have today where corporations basically tell you what you should buy, with the public generally going with the flow, favoring one good, component, or feature which, using price of course so if they don’t like something then clearly that wont produce it anymore to weed out supply and demand– this system works almost the opposite way.

The entire community has the option of presenting ideas for everyone to see and weigh in on and build upon... and whatever isn't of interest, simply wont be executed to begin with. There’s no testing here, such as you would see in marketing. It’s incredibly wasteful. It is as simple as that.

The actual mechanism of proposal, would come in the form of an interactive design interface - such as we see with Computer-Aided Design or CAD as it’s called - or more specifically Computer-Aided Engineering, which is a more complicated synergistic process.

And, as an aside, some see Computer-aided design programs, as they exist, as having an enormous learning curve and of course they do. But just as the first computers were very difficult code-based interfaces, which were later replaced by small little programs in the form of graphic icons that we’re all so familiar with – the future CAD type programs could be oriented in the exact same way – to make them more user friendly.

And obviously, not everyone has to engage in design. Some people, like most people today, they appreciate what’s been created prior, they absorb and would use what other people come up with . So there’s a diminishing law of returns in a lot of ways, if you will, not everyone has to get in there and have some role to do this, but many will and many will enjoy the process.And of course you can customize things as you go which is a great point, there’s minor things that can happen with a product that someone doesn’t know anything about but maybe they just want to change the color and that’s it. Obviously, that doesn’t take a lot of education. More importantly, technically speaking, the beauty of these design and engineering programs today is they incorporate advanced physics and other real world, natural law properties, so a good isn't just viewable in a static 3d model, it can be tested right there, digitally. And while some testing capacity might be limited today, it is simply a matter of focus to perfect such digital means.

For example in the automotive industry, long before new ideas are built they run them through similar digital testing processes... and there is no reason to believe that we will not eventually be able to digitally represent and imitate and set in motion virtually all known laws of nature in time, and being able to apply them to different contexts.

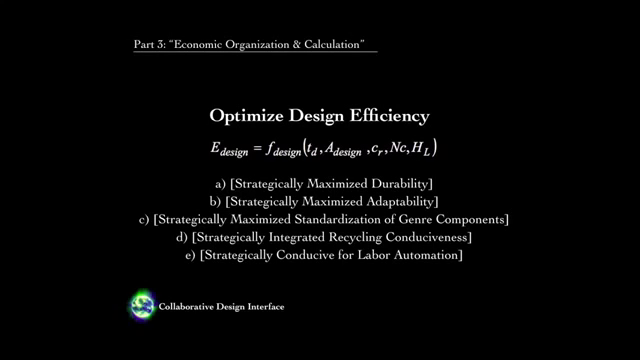

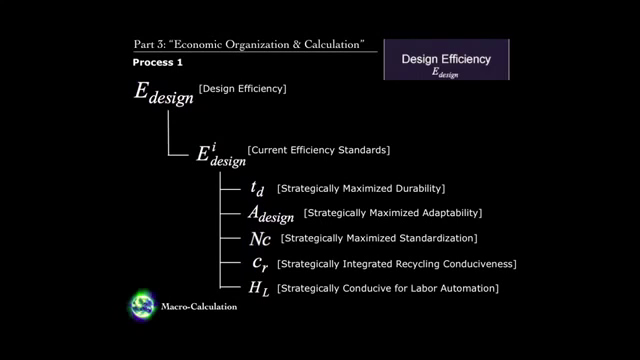

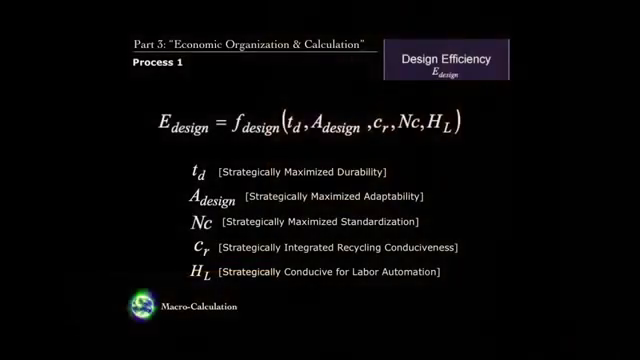

Similarly – and this is critical – this design as proposed of this system is filtered through a series of sustainability and efficiency protocols which relate to not only the state of the natural world but also the total industrial system in as far as what is capatable. Processes of evaluation and suggestion would include the following:

- Strategically Maximized Durability

- Adaptability

- Standardization of Genre Components

- Strategically Integrated Recycling Conduciveness, as I’ve mentioned before and

- Strategically Conducive designs themselves, making them conducive for Labor Automation

Durability just means to make the good as strong and as long lasting as relevant. The materials utilized, comparatively assuming possible substitutions due to levels of scarcity or other factors, would be dynamically calculated, likely automatically in fact by the design system, to be most conducive to an optimized durability standard.

Adaptability, this means that the highest state of flexibility for replacing component parts is made. Has anyone seen this thing called phone blocks? Where there, yeah, brilliant. In the event a component part of this good becomes defective or out of date of any good, wherever possible the design facilitates that such components are easily replaced to maximize full product life-span.

Standardization of Genre Components. All new designs either conform to or replace, if they’re updated, existing components which are either already in existence or outdated due to a comparative lack of efficiency. Many don't know this but a man named Eli Whitney, in 1801, was the first to really apply standardization in production. He made muskets and back then they were handmade and they were un-interchange. So the musket parts, if anything broke, you take apart from something else. He was the first to make the tools to do this and he basically started the entire process of standardization and the U.S. military was now able to buy high things of muskets and interchange them in much more sustainable [way] even though we were killing people. Which is interesting for the military, because if you think about it, the military is one of the most efficient systems on the planet, because it’s absent the market economy. If you really want to look towards where industrial efficiency was born, as much as I dislike it, the military is where it becomes, where it’s been harnessed the most.

So, anyway, this logic not only applies to a given product, it’s applied to the entire good genre, standardization.

And by the way this efficiency will never happen in a market economy with its basis in competition - as proprietary technology removes all such collaborative efficiency. No one wants that, no one wants to share everything like that. Otherwise, people wouldn’t have a need to go back to their company of the root company and buy the part, they would go somewhere else where they have access to it and other means.

Recycling Conduciveness, as noted before, this means every design must conform to the current state of regenerative possibility. The breakdown of any good must be anticipated and allowed for in the most optimized way, and

Made Conducive for Labor Automation – this means that the current state of optimized, automated production is directly taken into account, seeking to refine the design that’s submitted to be most conducive to the current state of production with the least amount of human labor or monitoring.

Again, we seek to simplify the way materials and production means are used so that the maximum number of goods can be produced with the least variation of materials and production equipment. It’s a very important point. And these five factors are what we could call, in total, the Optimized Design Efficiency function, if you want to be technical. Keep this in mind as I am going to return to it in a moment.[2]

The industrial complex

Moving on to the The Industrial Complex, the layout.This means the network of facilities which are directly connected to the design & database system I’ve just described.

Servers, production, distribution, recycling is basically it - also we’d need to relate the current state of resources, critically important, as per the Global Resource Management Network, another tier, which I’m going to also describe in a moment.

Production, this means of course actual manufacturing, would evolve, as expressed before, as automated factories which are increasingly able to produce more with less material inputs and less machines, ephemeralization. And if we are to consciously design out unnecessary levels of complexity, we can further this efficiency trend greatly with an ever lower environmental impact and resource use while maximizing our, again, abundance producing potential.

The number of production facilities, whether homogeneous or heterogeneous, as they would be called, would be strategically distributed topographically based around population statistics, very simple stuff– no different than how grocery stores today where they try to average distances as best they can between pockets of people and neighborhoods. You could call this the “Proximity Strategy”, which I’ll mention again in a moment. Distribution can either be directly from the production facility, as in the case of an on-demand, custom, one off production or it can be sent to a distribution library for public access in mass, based on demand interest in that region.The library system is where goods can be attained.

Some goods can be conducive to low demand, custom production and some will not be. Food is the easy example of a mass production necessity... while a personally tailored piece of furniture would come directly from the manufacturing facility once created.

I suspect, again, this on-demand process which will likely become equally as utilized as mass production will be an enormous advantage. As noted, on- demand production is more efficient since the resources are going be utilized for the exact use demand as opposed to the block things that we do today.

In the context of the distribution library, inventory is assessed in a dynamic, direct feedback link, of course, between production/distribution and demand.

If that doesn't make sense to you, again – all you have to think about is how inventory accounting and tracking in any major commercial distribution center today, with, of course a few adjustments made in this model. We’re already doing this type of stuff already.

And regardless of where the good is classified to go, whether it’s custom or not – libraries or to the direct user – this is still an 'access system'. In other words, at anytime, the user of the custom good can return the item for reprocessing, just as a person who obtained something from the library can as well.

Since, as noted, the good has been pre-optimized, all goods have been pre-optimized for conducive recycling, odds are the recycling facility is actually built directly into the production facility or the genre production facility depending on how many facilities you need to create the variety of demand.

So again – there’s no “trash” here. Whether it’s a phone, a couch, a computer, a jacket, a book – everything goes back to where it came from for direct reprocessing. Ideally this is a zero waste economy.

Resource Management, Feedback & Value

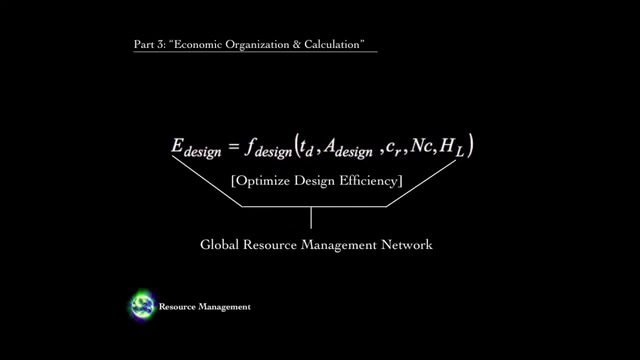

The Computer-aided and engineering design process obviously does not exist in a vacuum, processing demands input from the natural resources that we have.So, connected to this design process, literally built into the [Optimize Design Efficiency] function noted prior, is dynamic feedback from an earth-wide accounting system which gives data about all relevant resources which pertain to all productions.

Today, most major industries keep periodic data of their genre materials as far as how much they have but clearly it’s difficult to ascertain due to the nature of corporate secrets and the like. But it’s still done. Regardless, to whatever degree technically possible this is, all resources are tracked and monitored, in as close to real time ideally as possible. Why? Mainly because we need to maintain equilibrium with the earth's regenerative processes at all times, while also, as noted before, work to strategically maximize our use of the most abundant materials, while minimize anything with emerging scarcity.

Value

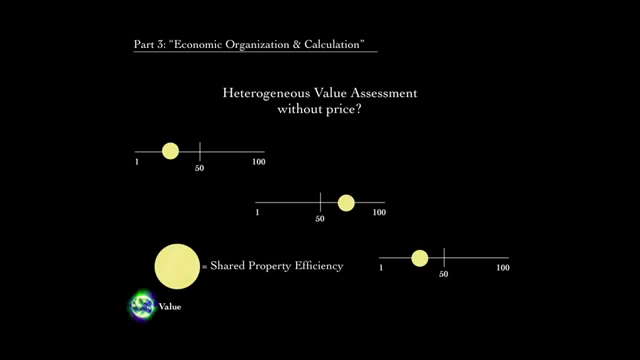

As far as Value, the two dominant measures, which will undergo constant dynamic recalculation through feedback as industry unfolds, is “scarcity” and “labor complexity.”Scarcity Value without a market system could be assigned, a numerical value. Say from 1 to 100. One would denote the most severe scarcity with respect to the current rate of use - and 100 the least severe. Fifty would mark the steady-state dividing line.

For example, if the use of wood lumber passes below the steady state level of 50 - which would mean consumption is currently surpassing the earth's natural regeneration rate - this would trigger a counter move of some kind - such as the process of 'material substitution' –hence the replacement for wood in any given future productions, finding alternatives.

And, of course, if you are free market mindset listening to this, you are likely going to object at this point by saying “without price- how can you compare value of one material to another or many materials?”

Simple - you organize genres or groups of similar use materials and quantify, as best you can, their related properties and degree of efficiency for a given purpose, and then you apply a general numerical value spectrum to those relationships as well.

For example, there are a spectrum of metals which have different efficiencies for electrical conductivity. These efficiencies can be quantified. And if they can be quantified, they can be compared. So if copper goes below the 50 median value regarding it’s scarcity, calculations are triggered by the management program to compare the state of other conducive materials in it’s database, compare their scarcity level and their efficiency – preparing for substitution and that kind-of information goes right back to the designer.

And naturally, this type of reasoning might, indeed, get extremely complicated as, again, these are numerous resources and numerous efficiencies and purposes. Which is exactly why it is calculated by machine, not people... and it’s also why it blows the price system out of the water, when it comes to true resource awareness and intelligent management.

"Labor complexity”. This simply means estimating the complexity of a given production. Complexity, in the context of an automated oriented industry can be quantified by defining and comparing the number of “process stages,” if you will. Any given good production can be foreshadowed as to how many of these “stages”of production processing it will take. It can then be compared to other good productions, ideally in the same genre, for a quantifiable assessment. The units of measurement are the stages, in other words. For example, a chair that can be molded in 3 minutes, from simple polymers in one process will have a lower ‘labor complexity’ value than a chair which requires automated assembly down a more tedious production chain with mixed materials.

In the event a given process value is too complex or inefficient in terms of what is currently possible or too inefficient by comparison to an already existing design of a similar nature as well, the design, along with other parameters, would be flagged and hence need to be reevaluated.

Again, all of this from feedback in the Design interface... and there is no reason not to assume that with ongoing advancement in AI, artificial intelligence, [the system] wouldn’t be able to feedback not only the highlight of the problem but it would also create suggestions or substitutions for you to understand in the interface.

Macro-Calculation

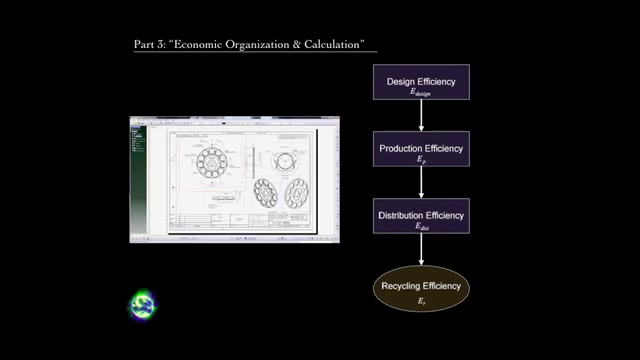

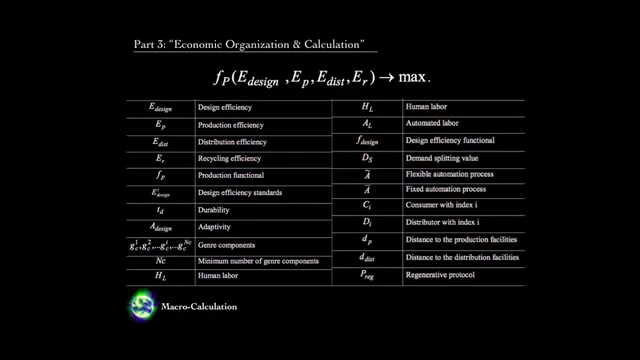

Okay. So let put some of this reasoning together and I hope everyone can bear with me. If we were to look at good design in the broadest possible way with respect to industrial unfolding, we would end up with about four functions or processes - each relating to the 4 dominant, linear stages of design, production, distribution, and recycling. The following propositions should be obvious enough as a rule structure. All Product Designs must adapt to [Optimized Design Efficiency]. They must all adapt to [Optimized Production Efficiency]. And they must adapt to [Optimized Distribution Efficiency]. And they must adapt to [Optimized Recycling Efficiency]. Seems redundant but this we have to think about it.Here is a linear block schematic, as shown before and the symbolic logic representation, which embodies the subprocesses or functions I’m now going to very generally break down.

Process 1

Process 1 , the design [Optimize Design Efficiency] A ‘Product Design' must meet or adapt to criteria set by what we will call [Current Efficiency Standards].This efficiency process has five evaluative subprocesses, as noted before earlier in the presentation:

- Durability

- Adaptability

- Standardization

- Recycling Conduciveness

- maximize automation conduciveness

So, in the end, when it comes to this design efficiency process set - we end up with this design function, at the top. And I’ll list, just to see it, I’ll list all of the functions meanings at the end.

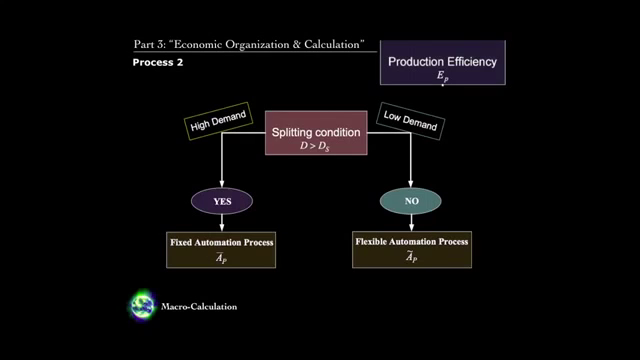

We move on to Process two- Production Efficiency.

Process 2

In short, this is the digital filter that moves design to one of two production facility types, one for high demand or mass goods and one for low demand for custom goods.The first uses Fixed automation - meaning unvaried production ideal for high demand; and the 2nd flexible automation which can do a variety of things but usually in shorter runs. This is a distinction that’s commonly made in traditional manufacturing terms.

This structure assumes only two type of facilities of course. Obviously there could be more based on the production factors, but if the design rules in the process are respected, as expressed before, there shouldn’t be much variety. And over time things get simpler and simpler.

So to state this, I’m just going to run through it for those that like to hear things spelled out like this: -All 'Product Designs' are filtered by a [Demand Class Determination] process - D. The [Demand Class

Determination] process filters based on the standards set for:

- [Low Demand] or

- [High Demand]

Also, Both the manufacturing of [Low Consumer Demand] & [High Consumer Demand] 'Product Designs' will be regionally allocated as per the [Proximity Strategy] of the manufacturing facility. This simply means you keep things as close to you as possible, as close to the average of any given demand as far as what type of facility you’re using. And this will change over time as populations change, so you keep updating.

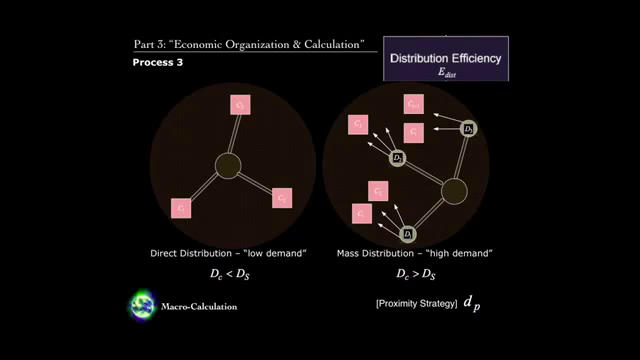

Process 3

Once process 2 is finished, the 'Product Design' is now a ‘Product' and it moves towards [Optimize Distribution Efficiency] in short, all 'Products' are allocated based on the ‘prior’ [Demand Class Determination] as noted before.So, [Low Consumer Demand] products follow a [Direct Distribution] process. [High Consumer Demand]s follow the [Mass Distribution] process - which would likely be the libraries in that case.

Both of course [Low Consumer Demand] & [High Consumer Demand] 'Products' will be regionally allocated per the [Proximity Strategy], as before.

Process 4

And Process 4, very simple . The 'Product" undergoes its life space. Ideally it’s been updated and adapted, ideally it’s been used to the highest degree and made as advanced as it could within its life cycle. And once it’s done and becomes "Void” it moves to process #4 which is simply [Optimized Recycling Efficiency]. All voided products will follow a regenerative protocol which is a subprocess that clearly I’m not going to go into because it’s deeply complicated and is the role of engineers to develop over time. And this is just a simple macro representation, again, these sub variable or sub processes go on quite a large degree.So, keeping all this in mind, again a lot of this will be in the text, and hopefully others I think can see this stuff better that are fluent with this type of thinking, hone in and perfect these equations and relationships. What I’ve tried to do here is to give a broad sense of how this type of thing unfolds.

Conclusion

As a concluding statement more or less, the way this extrapolation of sustainability, it’s really quite a simple logical thing. You don’t have to be a rocket scientist to see how things work on this level. So creating a real program that can factor in - what are hundreds if not thousands of subprocess in algorithmic form, as they pertain to such an economic complex, is indeed a massive project in and of itself, but more of a tedious project. You don’t need to be a genus to figure this stuff out. And I think this is an excellent think-tank program for anyone out there that’s interested in projects. I have number of little projects that I’m trying to get going when I have time and one is simply called The Global Redesign Institute, which is a macroeconomic approach to design the entire surface of the planet basically and then this other programming concept where you create an open source platform where people can begin to engineer this very program that I’m describing.And that’s it. I was going to make a conclusion section to this talk... but it was already way too long. So, I just hope this gives a deeper understanding of the model and how it could work and thank you for listening.

--

- ↑ Video via YouTube

- ↑ See 1:30:55 in the original full lecture

No comments:

Post a Comment