Blogger Reference Link http://www.p2pfoundation.net/Transfinancial_Economics

Article Ref Link Below Wikipedia

Procurement is the acquisition of goods, services or works from an external source. It is favourable that the goods, services or works are appropriate and that they are procured at the best possible cost to meet the needs of the purchaser in terms of quality and quantity, time, and location.[1] Corporations and public bodies often define processes intended to promote fair and open competition for their business while minimizing exposure to fraud and collusion.

Contents

[hide]Overview[edit]

Almost all purchasing decisions include factors such as delivery and handling, marginal benefit, and price fluctuations. Procurement generally involves making buying decisions under conditions of scarcity. If good data is available, it is good practice to make use of economic analysis methods such as cost-benefit analysis or cost-utility analysis.An important distinction made between analyses without risk and those with risk. Where risk is involved, either in the costs or the benefits, the concept of expected value may be employed.

| Direct procurement and indirect procurement | ||||

|---|---|---|---|---|

| TYPES | ||||

| Direct procurement | Indirect procurement | |||

| Raw material and production goods | Maintenance, repair, and operating supplies | Capital goods and services | ||

| F E A T U R E S | Quantity | Large | Low | Low |

| Frequency | High | Relatively high | Low | |

| Value | Industry specific | Low | High | |

| Nature | Operational | Tactical | Strategic | |

| Examples | Crude oil in petroleum industry | Lubricants, spare parts | Crude oil storage facilities | |

Direct procurement occurs in manufacturing settings only. It encompasses all items that are part of finished products, such as raw material, components and parts. Direct procurement, which is the focus in supply chain management, directly affects the production process of manufacturing firms. In contrast, Indirect procurement activities concern “operating resources” that a company purchases to enable its operations. It comprises a wide variety of goods and services, from standardized low value items like office supplies and machine lubricants to complex and costly products and services;[2][3] like heavy equipment and consulting services.

History[edit]

Prior to 1900, purchasing was recognized as an independent function by many railroad organizations, but not in most other industries.Prior to World War I, purchasing was regarded as primarily clerical.

During World War I & II - The function increased due to the importance of obtaining raw materials, supplies, and services needed to keep the factories and mines operating.

1950s & 1960s - Purchasing continued to gain stature as the techniques for performing the function became more refined and as the number of trained professionals increased. The emphasis became more managerial. With introduction of major public bodies and intergovernmental organizations, such as United Nations, procurement becomes a well-recognized science.

1970s & 1980s - More emphasis was placed on purchasing strategy as the ability to obtain needed items from suppliers at realistic prices increased.

1983 - In September 1983, Harvard Business Review published a ground-breaking article by Peter Kraljic on purchasing strategy that is widely cited today as the beginning of the transformation of the function from "purchasing", to something that is viewed as highly tactical to procurement or supply management, something that is viewed as very strategic to the business.

1990s - Procurement starts to become more integrated into the overall corporate strategy and a broad-based transformation of the business function is ignited, fueled strongly by the development of supply management software solutions which help automate the source-to-settle process.

2000s - The leader of the procurement function within many enterprises is established with a C-Level title - the Chief Procurement Officer (sometimes called the Head of Procurement). Websites, publications, and events, and that are dedicated solely to the advancement of Chief Procurement Officers and the procurement function arise. The global recession of 2008-2009 places procurement at the crux of business strategy.

2010s - The elevation of the function continues as Chief Procurement Officers are recognized as important business leaders and begin to take on broader operation responsibility.[4]

Topics[edit]

Procurement vs acquisition[edit]

The US Defense Acquisition University (DAU) defines procurement as the act of buying goods and services for the government.[5]DAU defines acquisition as the conceptualization, initiation, design, development, test, contracting, production, deployment, Logistics Support (LS), modification, and disposal of weapons and other systems, supplies, or services (including construction) to satisfy Department of Defense needs, intended for use in or in support of military missions.[5]

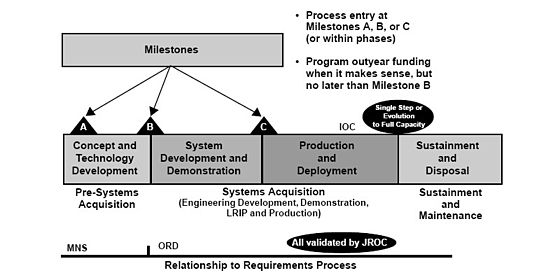

Acquisition is therefore a much wider concept than procurement, covering the whole life cycle of acquired systems. Multiple acquisition models exist, one of which is provided in the following section.

Acquisition process[edit]

The revised acquisition process for major systems in industry and defense is shown in the next figure. The process is defined by a series of phases during which technology is defined and matured into viable concepts, which are subsequently developed and readied for production, after which the systems produced are supported in the field.[6]- Concept and Technology Development: is intended to explore alternative concepts based on assessments of operational needs, technology readiness, risk, and affordability.

- Concept and Technology Development phase begins with concept exploration. During this stage, concept studies are undertaken to define alternative concepts and to provide information about capability and risk that would permit an objective comparison of competing concepts.

- System Development and Demonstration phase. This phase could be entered directly as a result of a technological opportunity and urgent user need, as well as having come through concept and technology development.

- The last, and longest phase is the Sustainable and Disposal phase of the program. During this phase all necessary activities are accomplished to maintain and sustain the system in the field in the most cost-effective manner possible.

Procurement systems[edit]

Another common procurement issue is the timing of purchases. Just-in-time is a system of timing the purchases of consumables so as to keep inventory costs low. Just-in-time is commonly used by Japanese companies but widely adopted by many global manufacturers from the 1990s onwards. Typically a framework agreement setting terms and price is created between a supplier and purchaser, and specific orders are then called-off as required.Procurement process[edit]

Procurement may involve bidding process known as tendering. A company or organisation may require some product or service. If the price exceeds a threshold that has been set (e.g.: government department procurement policy: "any product or service desired whose price is over X must be put to tender"), depending on policy or legal requirements, the purchaser is required to state what is required and make the contract open to the bidding process. The concept of total cost also comes into play. At times, not just price, but other factors such as reliability, quality, flexibility and timing, are considered in the tendering process. A number of potential suppliers then submit proposals of what they will provide and at what price. Then the purchaser will usually select the lowest bidder; however if the lowest bidder is deemed incompetent to provide what is required despite quoting the lowest price, the purchaser will select the lowest bidder deemed competent. In the European Union, strict rules on procurement must be followed by public bodies, with contract value thresholds determining the processes required (relating to advertising the contract, the actual process etc.).Procurement steps[edit]

Procurement life cycle in modern businesses usually consists of seven steps:- Identification of need: This is an internal step for a company that involves understanding of the company needs by establishing a short term strategy ( three to five years) followed by defining the technical direction and requirements.

- Supplier Identification: Once the company has answered important questions like: Make-buy, multiple vs. single suppliers, then it needs to identify who can provide the required product/service. There are many sources to search for supplier; more popular ones being Ariba, Alibaba, other suppliers and trade shows.

- Supplier Communication: When one or more suitable suppliers have been identified, requests for quotation, requests for proposals, requests for information or requests for tender may be advertised, or direct contact may be made with the suppliers. References for product/service quality are consulted, and any requirements for follow-up services including installation, maintenance, and warranty are investigated. Samples of the P/S being considered may be examined, or trials undertaken.

- Negotiation: Negotiations are undertaken, and price, availability, and customization possibilities are established. Delivery schedules are negotiated, and a contract to acquire the P/S is completed.

- Supplier Liaison: During this phase, the company evaluates the performance of the P/S and any accompanying service support, as they are consumed.Supplier scorecard is a popular tool for this purpose.When the P/S has been consumed or disposed of, the contract expires, or the product or service is to be re-ordered, company experience with the P/S is reviewed. If the P/S is to be re-ordered, the company determines whether to consider other suppliers or to continue with the same supplier.

- Logistics Management: Supplier preparation, expediting, shipment, delivery, and payment for the P/S are completed, based on contract terms. Installation and training may also be included.

- Additional Step - Tender Notification: Some institutions choose to use a notification service in order to raise the competition for the chosen opportunity. These systems can either be direct from their e-tendering software, or as a re-packaged notification from an external notification company.

Procurement performance[edit]

In July 2011, Ardent Partners, published a research report that presented a comprehensive, industry-wide view into what is happening in the world of procurement today by drawing on the experience, performance, and perspective of nearly 250 Chief Procurement Officers and other procurement executives. The report includes the main procurement performance and operational benchmarks that procurement leaders use to gauge the success of their organizations. This report found that the average procurement department manages 60.6% of total enterprise spend. This measure commonly called "spend under management" refers to the percentage of total enterprise spend (which includes all direct, indirect, and services spend) that a procurement organization manages or influences. The average procurement department also achieved an annual savings of 6.7% in the last reporting cycle, sourced 52.6% of its addressable spend, and has a contract compliance rate of 62.6%.[7]Public procurement[edit]

Main article: Government procurement

Public procurement generally is an important sector of the economy. In Europe, public procurement accounts for 16.3% of the Community GDP.[8]Green public procurement[edit]

In Green public procurement (GPP), contracting authorities and entities take environmental issues into account when tendering for goods or services. The goal is to reduce the impact of the procurement on human health and the environment.[9]In the European Union, the Commission has adopted its Communication on public procurement for a better environment, where proposes a political target of 50% Green public procurement to be reached by the Member States by the year 2010.[10]

Alternative procurement procedures[edit]

There are several alternatives to tendering which are available in formal procurement. One system which has gained increasing momentum in the construction industry and among developing economies is the Selection in planning process which enables project developers and equipment purchasers to make significant changes to their requirements with relative ease. The SIP process also enables vendors and contractors to respond with greater accuracy and competitiveness as a result of the generally longer lead times they are afforded.Procurement frauds[edit]

Procurement fraud can be defined as dishonestly obtaining an advantage, avoiding an obligation or causing a loss to public property or various means during procurement process by public servants, contractors or any other person involved in the procurement.[11] An example is the kickback, whereby a dishonest agent of the supplier pays a dishonest agent of the purchaser to select the supplier's bid, often at an inflated price.See also[edit]

Notes et references[edit]

Benslimane, Y.; Plaisent, M.; Bernard, P.: Investigating Search Costs and Coordination Costs in Electronic Markets: A Transaction Costs Economics Perspective, in: Electronic Markets, 15, 3, 2005, pp. 213–224. Van Mendell 5 step framework- Jump up ^ Weele, Arjan J. van (2010). Purchasing and Supply Chain Management: Analysis, Strategy, Planning and Practice (5th ed. ed.). Andover: Cengage Learning. ISBN 978-1-4080-1896-5.

- Jump up ^ Lewis, M.A. and Roehrich, J.K. (2009). Contracts, relationships and integration: Towards a model of the procurement of complex performance. International Journal of Procurement Management, 2(2):125-142.

- Jump up ^ Caldwell, N.D. Roehrich, J.K. and Davies, A.C. (2009). Procuring complex performance in construction: London Heathrow Terminal 5 and a private finance initiative Hospital. Journal of Purchasing and Supply Management15(3):178-186.

- Jump up ^ "Rackspace Appoints COO". Thefreelibrary.com. Retrieved 2013-06-16.

- ^ Jump up to: a b Glossary of Defense Acquisition Acronyms and Terms, 12th Edition (plus updates since publication) accessed on 22 April 2009, Defense Acquisition University

- ^ Jump up to: a b c Systems Engineering Fundamentals. Defense Acquisition University Press, 2001[dead link]

- Jump up ^ "Ardent Partners Research - CPO 2011: Innovative Ideas for the Decade Ahead".

- Jump up ^ "Public contracts - Your Europe - Business". Europa.eu. Retrieved 2013-06-16.

- Jump up ^ "EC.Europa.eu". EC.Europa.eu. Retrieved 2013-06-16.

- Jump up ^ "EC.europa.eu". EC.europa.eu. Retrieved 2013-06-16.

- Jump up ^ "Combating Procurement Frauds Author Dr Irfan Ahmad".

External links[edit]

| Look up procurement in Wiktionary, the free dictionary. |

- Buy Smart+ Green Procurement in Europe

- [1] Inspection.com.tr] (European Union)

- Federal Procurement Data System (US)

- Public procurement (European Union)

- Green public procurement, European Commission

- Systems Engineering Fundamentals. Defense Acquisition University Press, 2001

- Shaw, Felecia N., 2010. "The Power to Procure: A Look inside the City of Austin Procurement Program". Applied Research Projects, Texas State University-San Marcos

No comments:

Post a Comment